Work Experience Account (Pt. 2) - Mott Macdonald

22 min read

October 21, 2022

Mott Macdonald are an engineering consultancy based in the UK, but work in over 150 countries around the globe. They are a huge employee-owned corporation, and I visited the Cambridge Office for a week. It's just outside the train station, along with a load of other high-profile technology firms, and this specific Mott Macdonald (MottMac for short) specialises in water management. From sewers to dams, and rivers to pipelines, that office did it all.

Initial Impressions

After receiving the acceptance offer email from MottMac during my GCSEs, I was elated! The application process wasn't too difficult, but there were lots of questions to answer on their portal. A thanks goes to my careers advisor for helping me find the link!

As my first work experience at a large, professional firm, it was pretty exciting. I came in through the swirly doors, and the building receptionist directed me to the 2nd floor - I felt too lazy to walk up some stairs, so the lift it was.

When I arrived in the MottMac reception, I had to go through a sign in process on the iPad, and get a name tag printed - it had a cute little QR code that you could scan for all the information about me. On the lanyard was the name tag and access key card. I could now go anywhere :D

The receptionist showed me around, and we found my hosts for the week. Frans and Iranga - Iranga was an electronic engineer who was designing systems for all sorts of projects, whilst Frans was a surge analyst, ensuring that pipelines wouldn't break if a pump were to fail. Both were quite experienced. So after meeting the other work experience student (Max), we all had a chat about the space and what we'd be doing that week. I was a bit nervous that first hour, but Frans and Iranga did an awesome job in welcoming us.

We went to our desks (it seems that there's some desk reservation system in place - because we got the most sought-after desks in the office) and set up with our computers. Each desk was a plug-and-play type thing, where you'd connect your laptop to the dock and it would charge, connect the keyboard, mouse, ethernet, and 2 external monitors. It seems that this idea of using a laptop but docking it at a desk it is the future of office work, and I see it everywhere these days. It's obviously great for portability, and taking the laptop around the office to meeting rooms, but there isn't much computational power - and it does show (especially when Frans tried generating simulations)!

I began working at my desk for the week - and somehow got it messy within the first hour.

Anyway, the desks were very nice and I got a great feel for what it's like to work there early on. The office on the whole was very spacious, light, and professional. I really liked it - the vibe was chilled and friendly, but it had everything you'd need and expect in an office; including terribly inconsistent air con.

The Rest of Day 1

We got to work on our project for the week - there was a choice between designing a new high speed railway between London Euston and Birmingham, or re-designing Euston station. As a massive train-lover, this was awesome, and I had to choose the first one. The idea of the assignment was to emulate real projects that the engineers there would complete, but do it in a much more condensed time frame to gain a holistic perspective on what a consultant at MottMac does - it was designed by one of the electrical engineers there.

So I made myself comfy (with a hot chocolate), and began working through the intro material online.

I was given a temporary Microsoft account as part of their organisation, and had access to all the usual things in the Microsoft suite. I also had access to a portal through which I would complete my project.

Then it was lunch - with the mayor of Cambridge and Peterborough! He came to visit the company because MottMac does a lot of work for the surrounding community, and whilst he and the executives were undoubtedly striking a deal in the conference room, he also came to meet the engineers and talk to us.

He's a funny chap - used to be a doctor - but also very passionate and practical. He has an awesome, energetic character. Anyway, after a quick speech, we ate lunch that MottMac prepared and I happily took quite a few brownies!

I spoke to a lot of the staff during this time - learning about what all they do and their routes into the role. I also got an insight into the more social aspect of the job - which is to say, everyone has lots of fun together when they're not actually working.

Afterwards (including getting shouted at by a grumpy engineer for not having my lanyard on me), we had a long chat with Frans (and one of the newer employees in the team) about his exact job...

Frans' Job

So Frans studies surge analysis in both existing pipelines, and designs for future plans. He used to work more on the water pipelines, but now he primarily studies sewage systems. Pumps are needed in sewage systems because the water that comes out from a house is typically quite low, and we can't rely on gravity alone to transport the water to the right place.

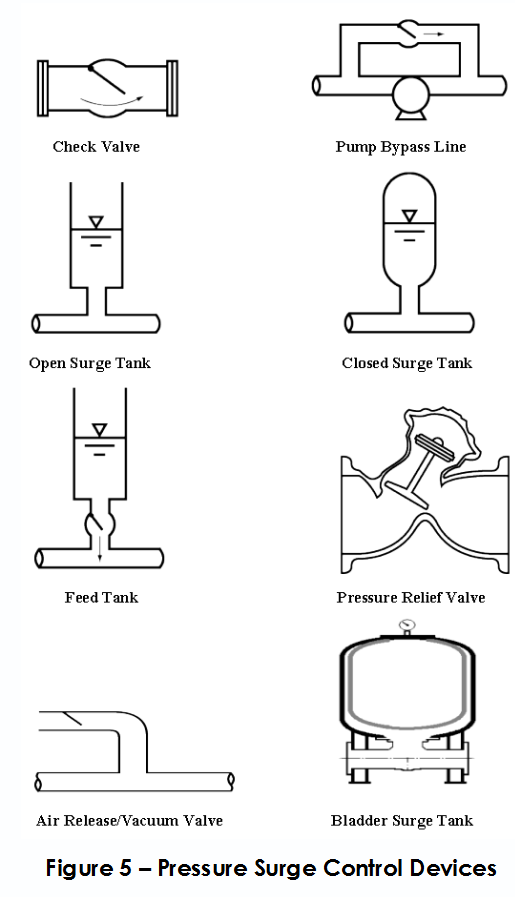

Hence we must use pumps. But pumps tend to fail every now and then. So when a pump fails in a pipeline (or any other transient event occurs), a wave is created in the fluid due to the difference in pressure. This causes a [pressure] surge, and these are dangerous because if there is too much pressure in the pipeline, then it could explode or damage equipment. However, at least in water distribution pipelines, we always want a positive pressure in the pipeline because it reduces the chance of external debris and fluids entering the pipes - Frans ensures it remains positive even when a pump fails.

Anyway, so Frans learns how to deal with all of these things, and uses both water and air valves to prevent excessive pressure build up in the waves. The air valves are used in sewage systems as they don't need to be watertight (the water is dirty anyway), and the more complicated water valves (surge tanks) are used in water systems - the level of the water in the valve varies depending on the pressure, so the waves' energy doesn't go into the pipe walls, but instead into the water valve, dampening its effect.

Some types of valves that Frans could use in his job! It's quite fun seeing all the different designs, and figuring out how they work to alleviate pressure surges.

There's a lot in his job, and Frans taught us so much, scribbling things and drawing diagrams in his pocket notebook as he went along, which I don't have time to explain here but the topic of surge analysis and pipelines is actually extremely interesting, and uses plenty of cool physics.

Finally, Frans showed us his program and the type of files that he would work with. The program was very cool, but he also told us that it cost the company thousands of pounds - expected with such specialised and niche software. Back in the day, they used to have to do all the calculations by hand which would have taken a very, very long time. But because Frans can just simulate everything on his computer, it makes valve positioning a significantly easier task.

He showed us a model of a pipeline system before he worked on preventing pressure surges, and then he also showed us one afterwards. There was a clear difference in the pressure across the pipeline and the graphs and diagrams were all awesome to see. It seems that, everywhere you look in the engineering industry, there is a really small niche that still requires so much knowledge and skill, and there's always something in that niche to tickle your brain.

The Rest of the Week Pt. 1

The rest of the week was much of the same thing - talking to lots of employees from apprentices to senior engineers, working on my project, drinking too much hot chocolate, and having a great time. The hot chocolate machine was spiffing, if I haven't yet mentioned that!

The company is organised into a whole load of groups, and there is a leader/manager for each team within a group. I met Frans' manager and it seems like the dynamic between them was just like any other employee - they worked next to each other on the same desk, and talked loads. I love this about engineering firms - how most of the senior people work right alongside those below them. It helps to fracture the serious and pressurising nature of the job, contrasting the prescriptive company structure in the largest of companies.

We also had a chat with some electrical engineers about their role and routes. It was in a meeting room - what was quite cool was the system of booking a meeting in a conference room. The conference room would effectively have its own Microsoft account, and you'd have to schedule a meeting with the room (and whoever else you wanted) to book it. The room's schedule would then appear on a nifty display on the central table. They also had the cliché whiteboard wall which I may or may not have drawn on...

Anyway, back to the electronic engineers! There were 3 of them - all were quite experienced. They showed us some of the files they'd be working on - one was like 75 pages of just circuit diagrams (which Iranga struggled to decipher). They all did slightly different things, but they would all still have to work with other people across departments and companies seemingly more than the other engineers. The work varied from creating the circuits in the first place, to auditing and checking circuits that were already made, system design of an entire project, or system design of a specific facet of the project. It was amazing to see 3 extremely intelligent minds all in one room and interacting with us.

The most experienced engineer was actually very interesting - she had worked at the company for a long while, and therefore had the respect to ask to only be assigned projects worth over £10 million - she really liked massive projects. In fact, she planned to take her kids and husband on a trip to a dam she was almost done with and show them her work. Mainly because her husband was a civil engineer (not an electronic one) and therefore she wanted to convince her family that her job was far better!

The point being that, you can almost choose what projects to work on. There is a manager who assigns everyone in the office projects as they come in from clients, and you can give your preferences to the manager who will try their best to stick to them. And, of course, the most trusted engineers have the highest preference priority.

The rest of the 90 minute conversation revolved around all sorts of things, but the key point was that being an electronic engineer is very fun. They'd sometimes go to client's factories to ensure that the product being manufactured was actually the same as their specification. So to test the product, they'd have to press every button and mess with it until it breaks - and if it doesn't break, then the product is well made and very electrically robust. They really did sound like toddlers at this point!

Iranga was one of the 3 engineers, and I told him that I quite like electronics but wasn't sure if it was a good job for me. I said that it was more of a hobby and really fun thing, as opposed to something I want to do in an employed position. But he was quick to snap back a response - saying he was also just like that, but he still has plenty of time to do his own electronic projects such as an AI camera robot thing. Iranga also goes to Makerspace in Cambridge. It was great to know that Iranga did this, and even if his job wasn't just making random projects for fun, he had the ability and drive to continue doing that in his free time. Big respect for him.

He talked about personal development too, and how the company was very willing to pay for an IT certification (networking I think it was?) that he wanted to get. Iranga generally seemed to be in support of MottMac as a company, and told me how they really focus on professional development which can help you move divisions if you ever want to switch your specialty.

Anyway, overall it seems that electronic engineering is an awesome path to go down, and I'm now seriously considering it as a career option.

Another person we talked to was Joe, who was doing a degree apprenticeship there. He talked about his experience and how he managed it. I quite like the concept of a degree apprenticeship but typically you can't go to a top tier uni (I'm aspiring for Imperial) which is not ideal. However, you still achieve a degree and spend 20% of your contracted time studying. It can be split in different ways, such as 1 week out of every 5, or 1 day out of every working week.

Joe said he felt as if he developed faster and was more mature than his friends who had gone to uni in a conventional manner. And he also said that he studied his degree with a class of just degree apprenticeships, which ensured that they were all similar in progress and intelligence. His contract with MottMac was for 5 years, and Joe seemed to really enjoy it. I'll probably apply to a few just in case I don't get into a top tier uni, and explore the options from there! I'm all for doing more practical work as opposed to just sitting in a classroom and learning things - which I despise - and a degree apprenticeship would let me learn the theory I need and gain the qualifications I need, but also have a lot of fun and provide real value to society. That's actually why I much prefer Imperial over Oxbridge, the latter having a huge emphasis on theory only. Thanks, Joe!

Finally, there was also an Interns' Tea organised, which we were invited to. I got to speak to many people there and figure more about which uni I would want to go to, and what an internship is like at MottMac. They were all quite positive, and echoed the same idea that I should just do what I love and see where it takes me - engineering is such a vague umbrella term and it encompasses almost every possible facet of life. Based off what they said, I'll probably apply to a MottMac internship during my time at Uni to help figure out what exactly I want to do.

Oh, and I ate a tad too many jam doughnuts at the tea...

Wednesday had train strikes, so neither of us could come in (Max lives in Peterborough). We spent the day working from home, on our project. So it's about time I told you about it!

The Project

Just in case you forgot, we had to research, design, plan, budget, and finally pitch our business case for a high speed railway between Euston (London) and Birmingham. The project involved many, many hours of work, so I'll only touch on some key parts of it!

The key tasks were:

- Research the current solutions

- Identify what can be improved

- Design the route

- Design the rolling stock

- Design the timetable

- Budget the project

- Provide a timeline

- Combine everything to produce a convincing strategic business case

- Reflect upon my project

- Present my new railway to industry experts

That's a lot, so let's get cracking...

Designing the route was quite hard. Very hard. It was a 160km route and I had to choose where every bit of it would go. After plenty of consideration, I settled on a fairly direct route and tried to avoid as many settlements as possible to reduce regional disruption and costs. I looked at the planned HS2 track for inspiration, learning what's acceptable in a route and what isn't - it turns out that you can build a track through as many farms as you want!

After drawing the route in Google Earth, I had to count what was along the path - how many bridges, heritage sites, rail crossings, and significant natural landscapes the track cut through. This would help determine the cost of the project, as well as influence how the public consultation would pan out. On the whole, I designed a very direct route, justifying it by claiming it's a commuter service designed to truly connect the cities as fast and reliably as possible. It's a high speed business link, which would be critical in reducing the north-south inequality divide. After looking at several factors, such as the 21 year life expectancy difference between the two cities, I concluded that it would be a vital service.

If you're interested in what my route actually was in the end, you can check it out here.

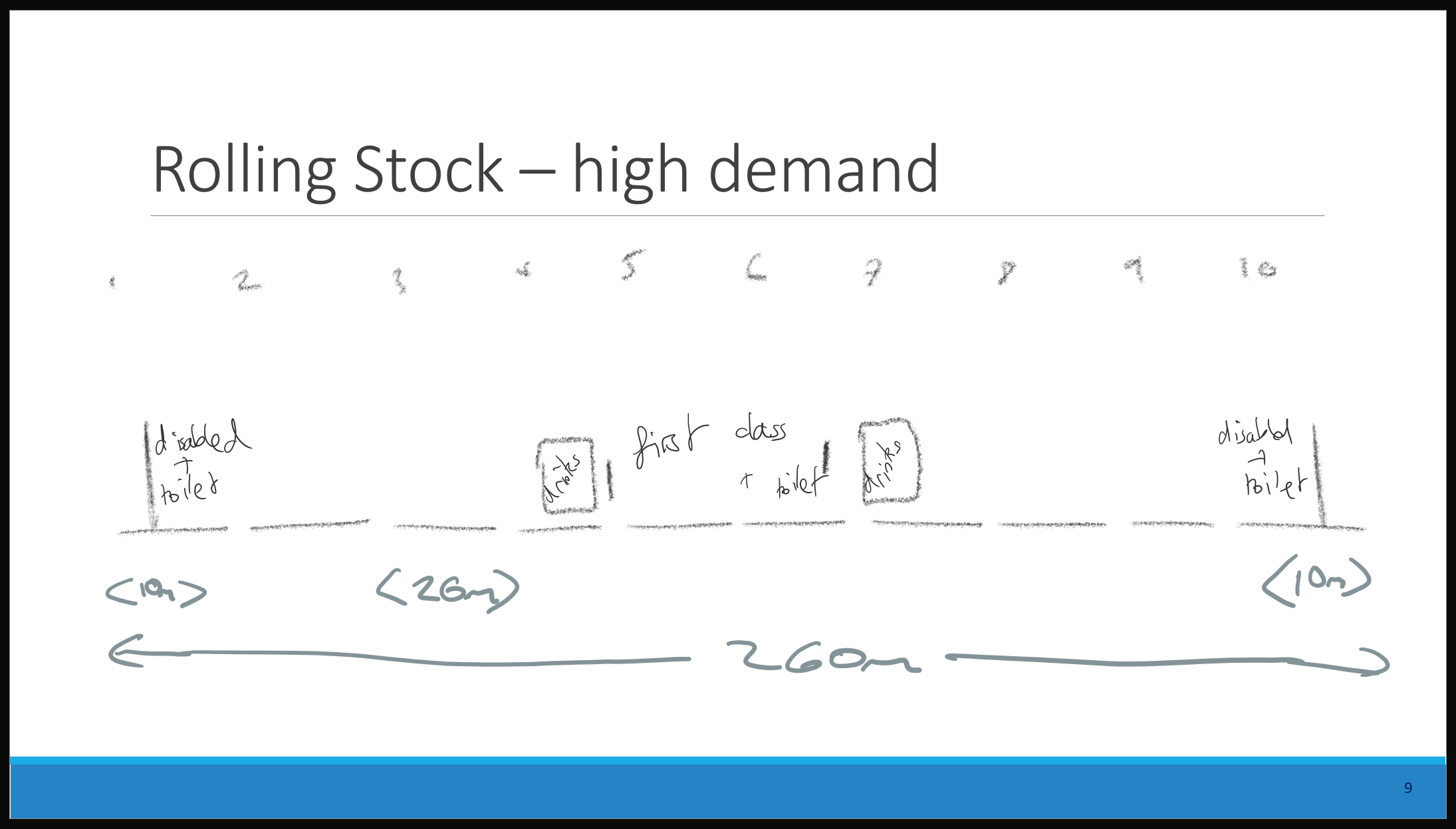

Next up was the rolling stock, aka the trains. I have no clue why I have to call them rolling stock, but I just do. Anyway, for the rolling stock itself, I was given a few options, and chose a nice balance between cost, capacity, and speed.

My rolling stock layout for the high-capacity services.

I created both a smaller train (6 carriages) and a larger train (10 carriages) for low and high demand respectively. Designed with a greater emphasis on efficiency and usability over experience, the train journeys would only be around 30 minutes long anyway. Oh, and of course there was first class with all the perks you'd want and expect when paying too much.

One pretty neat thing on the rolling stock was the internet - powered by Starlink. According to the Spring 2020 Transport Focus report, only 38% of travellers were happy with onboard WiFi. And as onboard WiFi typically uses regional mobile masts (HSDPA - effectively enhanced 3G), which would provide high-latency slow-speed internet, I clearly needed a completely new approach. Satellite internet offers a consistent, high-speed connection from anywhere; perfect for a fast-moving train in the middle of nowhere.

Alongside designing the premium first class experience (putting an emphasis on business users), I made a timetable, using Government-endorsed data to consider peak times and train load. I kept in mind the idea of induced demand too, ensuring there was plenty of capacity when needed - spacious trains really elevate the journey!

Budgeting and providing a timeline for construction was pretty hard. I did plenty and plenty of research to find the most realistic figures, and after spending a whole day crunching numbers, I ended up with an estimated cost of £6.5 billion - plus a £500 million contingency pot in case anything went wrong (hopefully not as wrong as HS2 though...).

Budgeting was quite a long-winded process!

Finally, the reflection. To try and keep this as honest and spontaneous as possible, I tried to not think about it too hard until my presentation. The presentation itself was great fun, and we had both Iranga and Frans watching, along with a senior engineer who was a train enthusiast. Hamish "the train guy" was meant to watch too, but he had a lot of work with deadlines that evening - Iranga said Fridays are always either really relaxed, or stressed as you can either have nothing or everything to do. At least we still had the senior engineer! He'd worked on numerous train projects before, so he had tonnes of insight to offer. He talked about his own work on HS2, and why it was so delayed. When it comes to a project as large as that, planning for every possible scenario is next to impossible, but there are also a load of things that you don't really have the foresight to see - one such example is when the construction of the railway was partially blocking the entrance to a canoeing club, so the engineer had to design a new entrance, and relocate the current one to keep the club happy and begin HS2 work.

There seems to be lots of issues with keeping the public happy, and even the Government can get a little fussy when it comes to Heritage sites - Iranga jumped on me when I said my route cuts through a site! One key thing I got exposed to more that week was the geographical and environmental side of things. Environmental engineering is a thing! They also had geographers in the office, who would help survey the land and conduct experiments on terrain before any project.

In fact, many of the engineers there did Geography A-Level, and I did see some transferrable skills myself. A lot of the analytical thinking and general knowledge that they acquired in the geography course really seems to have helped - even the GCSE course helped me with my rail project. All of our Geography teacher propaganda about how great the subject is actually seems to be true! Anyway, after our presentation, we had a chat with the experts about their thoughts, who offered some great insights and feedback that I'll definitely take forward.

And if you want to see all my project resources for the week, feel free to download them here.

The Rest of the Week Pt. 2

On Thursday, we had chats with some of the most seasoned employees at the company. The first chat was with civil engineer Tim Hill, and I'll remember that name forever. His passion was immense. You would never believe how passionate one could be about dams; it literally radiated off him and I really enjoyed his presentation.

Until a decade or two ago, there would be a lot of opportunities to go abroad under the company and work in other locations for up to a few years, surveying areas or overseeing construction projects. Lots of the staff there said this was a highlight of their job (they'd take their family with them), although with the sheer advance in technology and education, it doesn't happen a whole lot anymore.

Tim told us about his most interesting trip, where he was overseeing the construction of a dam he designed. They had contracted some locals, but there was a snowstorm one day and the workers were all out. So they found a small van nearby and squeezed into it - having no idea where to actually go. The van was low on fuel, so they couldn't stay in for long but they eventually found a small temporary coffee shop/stand. So then they all had to squeeze inside that (which had a heater)! After the snowstorm (about 24 hours later), the team went looking for the contractors and they were all so annoyed at what happened that the company was forced to buy an extremely expensive rescue vehicle thing. It was essentially a commercial military tank!

Tim also did a load of work in Egypt, analysing dams, designing dams, and teaching the locals new skills. He'd spent a lot of his career in Egypt and knew so much about the culture and history there, divulging into a long story about dams on the Nile.

The Aswan Dam, Egypt. MottMac has been involved in this dam for 100 years, and it provides great benefit for Egypt, such as controlled irrigation and hydroelectricity.

Anyway, Tim showed us some of his dams, and places he'd been to off the island. One huge dam he designed curved in two axes to keep any given point on it in stress against the water behind it and therefore make it self-supporting despite its massive size. Tim showed us the design process of a dam too. He was very good at his job, and is now more in management at MottMac, after having earned the right to be on the UK's exclusive board of elite engineers who have to survey and check dams frequently during their lifetime. I also learned what a chartered engineer is, and finally realised why all the unchartered, young engineers are made fun of by the older ones!

Next up was an even more senior engineer. He'd been working at the company for too long to remember(!), but loved his role as an engineer so much that he never went into management. He talked about his experience of uni, mostly, but he did study in a completely different era to us. He also gave some pretty awesome interview advice!

One thing that struck me the most about his experience is that many decades back, you could do almost anything you wanted to - so few people went to uni, and most roles didn't require specific qualifications. He just landed at MottMac by chance and liked it! Unfortunately, everything has changed since then, but thankfully I'm so set on engineering that it shouldn't be an issue for me.

He also spoke about the company on the whole, and talked about how it's employee owned so a large corporation can't just buy it and change the way it works or runs. The security of being in the company was also excellent, because MottMac values their employees incredibly high - unlike big tech such as Amazon who would cycle through employees faster than Bolt can run.

During the global recession of 2008, MottMac suddenly lost a lot of clients and therefore weren't bringing in enough money, and had staff that didn't have anything to do. However, they still kept all the staff employed, and either let them have paid holiday (most of the salary was still paid), or go abroad and almost be 'hired' by other engineering firms. This idea of employee-value is the sentiment across the company, so MottMac would be a fantastic option for job security, not to mention that the world will always need engineers who design and make pipelines and dams so even if MottMac collapsed, the engineers would still be in demand and be able to quickly get a new job. But civil engineering isn't for me!

Ah, and during lunch on the last day, John Goodricke (my friend's dad) came to visit us. He is a Technical Principal at the company, and we had a small chat about the week and one of his projects for HS2. John was great to talk to!

On the topic of lunch, after the first day (when we all had lunch for free with the mayor), I'd walk down - with Max and whoever else - a couple of minutes and buy something from Tesco, or treat myself to Wasabi. A surprisingly large amount of staff bought their food instead of pre-preparing and packing it.

Right at the end, I also had a chat with Frans about what he's currently working on (I heard CFD being mentioned!). He was on a project to try and optimise the sewage systems of London, and increase the flow rate of storm water into the Thames. He had a CAD file of the current design of a pipe exit, and lots of images showing snapshots of CFD simulations in a very long report (so long that ctrl-f was too laggy to use). It was quite cool to see this type of work in real life.

There was too much turbulent flow, and so the water wasn't going through as fast as it could. Considering all the issues England has with storm water mixing with sewage water and then overflowing into the sea/lakes/rivers, this project was pretty important. The issue with England is that it was one of the first civilisations to revolutionise and therefore make pipelines - long before humanity realised that we need two separate systems for storm water and sewage!

Frans taught me about Finite Element Modelling, explaining how it works - essentially, the computer splits an object into a large number of small blocks and if we know the properties of the material, along with the starting state of a few blocks, then the computer can crunch numbers to calculate the rest (spreading out through adjacent blocks) and hence simulate whatever scenario is needed on an entire model. His first year of uni was basically exclusively FEM, and he even had to code his own program in C to run on a basic model!

Then, after Iranga came back from his meeting, we all said goodbye and parted ways.

Reflecting Back

That week was absolutely awesome. I learned incredible amounts from all the engineers there, and a huge huge thanks to Frans and Iranga for taking the effort to ensure I had a really memorable time. Frans said he did two work experiences when he was younger; one where he was just left alone in the corner, and the other where he talked to people a lot, enjoyed it, and found great value in it. At the start of the week, Frans said he aimed to try make ours like his second. I think he succeeded!

They both supported me throughout my project, questioning my decisions and forcing me to think like an engineer. I had to strike the right balance of all the countless factors for every choice I made, justifying my actions and digging around online to find stats - an essential tool in informed decision-making. And if I didn't do this efficiently enough, I would fall behind schedule.

As a train-lover, the project also spawned lots of wider reading around trains. I discovered so much about the very vehicles I commute twice a day in - and it was cool to see the concept in action right after learning it. I'm glad to have earned my Industrial Cadets Silver award too.

This was the perfect way to get my EDT Industrial Cadets Silver award, and the perfect satisfying finish to the week!

I ended the week knowing much more than when I started, finding it a valuable experience for discovering career routes and drastically improving my awareness of the industry, alongside the workspace. It's definitely worth applying to if you're interested in engineering, and a final big thanks to everyone in the Cambridge office that week - it was fabulous :D

copied!

failed to copy!